-

In the petroleum refining, petrochemical and chemical manufacturing, natural gas processing and power generation industries, the term relief valve is associated with the terms pressure relief valve (PRV), pressure safety valve (PSV) and safety valve and is a type of valve used to control or limit the pressure in a system or vessel which can build up by a process upset, instrument or equipment failure, or fire.

The pressure is relieved by allowing the pressurised fluid to flow from an auxiliary passage out of the system. The relief valve is designed or set to open at a predetermined set pressure to protect pressure vessels and other equipment from being subjected to pressures that exceed their design limits.

- Pressure relief valve (PRV) or pressure safety valve (PSV): The difference is that PSVs have a manual lever to activate the valve in case of emergency. Most PRVs are spring operated. At lower pressures some use a diaphragm in place of a spring. The oldest PRV designs use a weight to seal the valve.

- Set pressure: When the system pressure increases to this value, the PRV opens. The accuracy of the set pressure often follows guidelines set by the American Society of Mechanical Engineers (ASME).

- Relief valve (RV): A valve used on a liquid service, which opens proportionally as the increasing pressure overcomes the spring pressure.

- Safety valve (SV): Used in gas service. Most SVs are full lift or snap acting, in that they pop completely open.

- Safety relief valve (SRV): A relief valve that can be used for gas or liquid service. However, the set pressure will usually only be accurate for one type of fluid at a time.

- Pilot-operated relief valve (POSRV, PORV, POPRV): A device that relieves by remote command from a pilot valve which is connected to the upstream system pressure.

- Low-pressure safety valve (LPSV): An automatic system that relieves by the static pressure of a gas. The relieving pressure is small and near the atmospheric pressure.

- Vacuum pressure safety valve (VPSV): An automatic system that relieves by the static pressure of a gas. The relieving pressure is small, negative and near the atmospheric pressure.

- Low and vacuum pressure safety valve (LVPSV): An automatic system that relieves by the static pressure of a gas. The relieving pressure is small, negative or positive, and near the atmospheric pressure.

- Pressure vacuum release valve (PVRV): A combination of a vacuum pressure and a relief valve in one housing. Used on storage tanks for liquids to prevent implosion or over pressure.

- Snap acting: The opposite of modulating, refers to a valve that “pops” open. It snaps into full lift in milliseconds. Usually accomplished with a skirt on the disc so that the fluid passing the seat suddenly affects a larger area and creates more lifting force.

- Modulating: Opens in proportion to the overpressure.

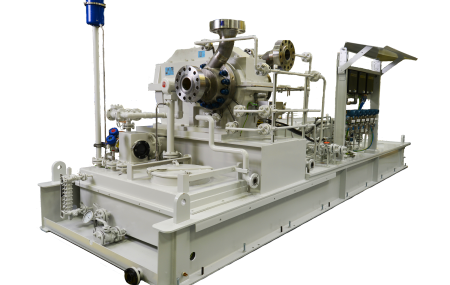

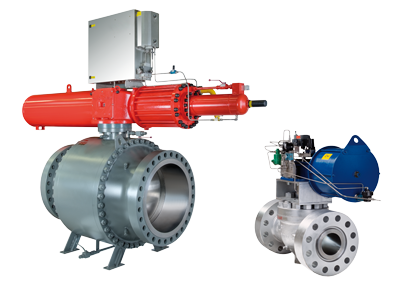

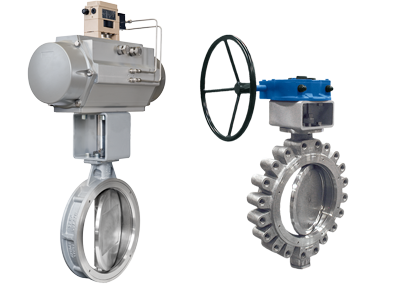

Sonwaysupply is able to provide you all required safety valves from reputable manufactures all around the world.

Related

-

API Std 520, API Std 521, API Std 526, API Std 527, A PI Guide for Inspection of Refinery Equipment

Chapter XVI Pressure Relieving Devices

ASME B31.1, ASME B16.5, ASME B16.34, ASME B31.8, ASME B 95.1, ASME B31.4.

MSS SP-25, MSS SP-55, MSS SP-61.

-